2000KVA Pad Mounted Transformer Internation - Daelim Belefic USA & Canada

2022-03-01 | Company News

There are many different rated capacities for three-phase pad-mounted transformers, from 45kVA to over 5000kVA. In these different capacities, 2000kva is a very common capacity in data centers, bitcoin mining farms, and solar projects. Daelim has already sold over hundreds of 2000kva transformers to North America and Latin American countries. Today’s article we will have a detailed review of Daelim 2000kVA Pad-mounted Transformer.

Combined with a high-voltage receiving section that combines the transformer, load switch, and protective fuse device, and metering associated with the low-voltage distribution section, this 2000 kva three phase pad-mounted transformer is a complete set of high-voltage transformers. Technology, a brand-new set of transformers and distribution equipment developed in conjunction with real-life

It is widely used in power distribution systems, particularly in the construction and transformation of urban and rural power grids, and is widely used in industrial parks because a 2000 kVA three-phase pad-mounted transformer has features such as small size, low investment, convenient operation, fast installation, and simple maintenance. , Residential quarters, commercial centers and high-rise buildings, and other occasions.

A number of scientific research results have been applied to the design of the 2000 kva three-phase pad-mounted transformers, such as a new insulation type and improvements to short-circuit resistance.

Technology and equipment of the highest quality have been used to achieve the highest level of performance.

There is an average 10.25% reduction in no-load loss, a 37.9% reduction in no-load current, and a 22.4% reduction in load loss when compared with the S7 series.

The iron core is a fully inclined three-stage joint laminated structure, and the no-load loss and no-load current are lower than the old products;

A copper wire is wound into both the high-voltage and low-voltage windings, the high-voltage winding adopts a cylinder structure with multiple layers, and the low-voltage winding adopts a cylindrical structure with an improved spiral structure;

With the new insulation structure, it has excellent short-circuit resistance;

Replace old components and fasteners with new ones

1. 2000 KVA Pad Mount Transformer Technical Specification

Rated capacity: 2000kVA

Input Voltage: 34.5kV, 24.94kV, 13.8kV, 12.94kV, etc... Dual voltage is available.

Output Voltage: 415/240V, 480/277V, etc...

Frequency: 60Hz / 50Hz

Feed Configuration: Loop-feed (6*HV Bushings) / Radial-feed (3* HV Bushings)

Connection Group: Dyn1 / YNyn0

2. 2000 KVA Pad Mount Transformer Dimensions

Transformer part of the 2000 kva three phase pad mounted transformer and control cabinet part of the transformer.

Transformers have a fully sealed structure, and the insulating oil can be either high ignition point oil or ordinary oil.

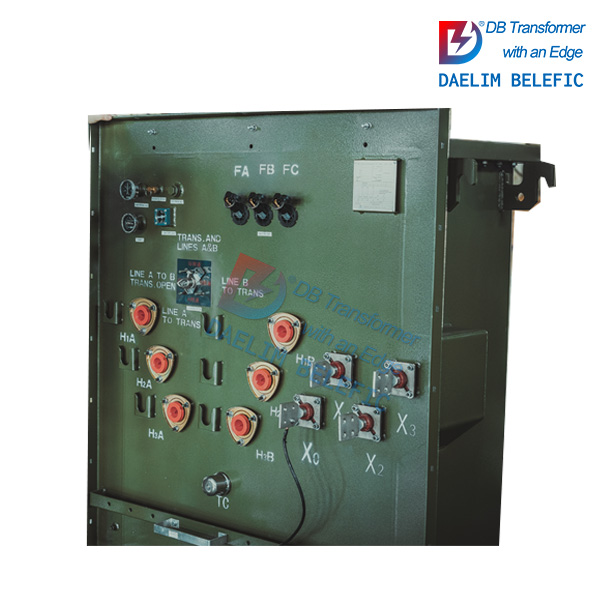

High-voltage and low-voltage control rooms are separated in the control cabinet.

High-voltage rooms are equipped with: a high-voltage cable plug, a lightning arrester, an operating handle for the load switch, non-excitation control taps, plug-in fuses, a thermometer, a pressure gauge, a gear oil position indicator, an oil filling plug, and an oil drain valve, all of which are submerged in transformer oil along with the transformer core.

High-voltage cables are connected to transformers with elbow connectors.

Electric energy meters, ammeters and voltmeters can be installed on the low voltage side, as can air circuit breakers, current transformers, and output circuits and capacitance compensation devices according to the user's needs.

Based on Daelim’s previous design, the 2000 kVA transformer dimensions are Height: 2145mm; Width: 1800mm; Depth: 2050mm.

The total weight is 6000kg, and the oil weight is 1820L.

You can put 3 units in a 40HQ container and 2 units in a 20GP container to the USA.

3. 2000 KVA Pad Mount Transformer Accessories

The metering and switch of the low-voltage power distribution part are combined with the transformer, the load switch, and the protective fuse device of the 2000 kVA three phase pad-mounted transformer. Technological development combined with actual conditions to create a complete set of transformer and distribution equipment.

It is widely used in power distribution systems, particularly in the construction and transformation of urban and rural power grids, and is widely used in industrial parks because a 2000 kVA three phase pad mounted transformer has features such as small size, low investment, convenient operation, fast installation, and simple maintenance. , Residential quarters, commercial centers and high-rise buildings, and other occasions.

BAYONET FUSES

A bayonet fuse is better for use in a two-fuse protection plan with a current-limiting backup fuse. ... The two fuses are connected into series, and are harmonious so that the current-limiting fuse conducts only upon internal equipment failure.

Most distribution cutouts have fuse characters made from tin or silver alloy wires that melt when exposed to a high enough current. To reduce surge duration and damage to the transformer and fuse holder, the released spring pulls the fuse link out of the fuse holder tube when the fuse blows.

Core and Coil

During the current flow through the windings of the transformer, known as coils, the core provides a controlled path for the magnetic flux created within the transformer. Electrical power is sent to the load from the output side or secondary side of the transformer.

Transformers with cores have windings built on two limbs and one flux path, and windings circumvent the core. Typically, high voltage transformers are used in transmission and distribution systems, as well as in automatic transformers.

HV LV Bushings

Transformer bushings are insulating structures that allow current-conducting conductors to pass through the grounded tank of the transformer. Transformer high voltage windings have bushings that are capacitor-graded, designed for higher voltage ratings.

Windings

The primary winding is the coil that draws power from the source. The secondary winding is the coil that carries the power to the primary winding. To deliver power to the load, the secondary coil delivers the transformed or changed voltage.

Tank

The volume of oil inside the transformer increases when the transformer is loaded and when ambient temperatures rise. Transformers provide adequate space for the expandable transformer oil in the conservator tank.

Among its uses are some types of oil-filled transformers, capacitors of high voltage, fluorescent lamps, circuit breakers, and switches of high voltage. As a coolant, it is able to serve three purposes: insulating, suppressing corona discharge and suppressing arcs.

Oil

Despite modern technology, mineral oil still fills most transformers. There are several types of oil to choose from, and other types are becoming more and more popular as well. Other alternative fluids possess benefits such as high fire and flash points for indoor use or environmental friendliness.

Thermometer

Otis provides accurate measurement of the oil temperature within transformers, also known as transformer oil temperature indicators.

Pressure Relief Valve

The Transformer industry generally classifies pressure relief devices as safety or protection equipment. Devices such as these are used to control oil pressure surges within oil cooled transformer tanks that breathe freely.

Cooling fans

Transformer cooling fans are sturdy, weatherproof fans for accelerating the cooling process in oil-cooled electrical transformers. They circulate air around the exterior of the transformer's radiator as oil works its way through the inside to dissipate heat and reduce the operating temperature of the transformer.

Tap Changer

The purpose of a tap changer is to regulate the output voltage of a transformer by altering the number of turns in one winding and thereby changing the turns ratio of the transformer.

The tap changer is placed on high voltage side because: ... Because of high voltage the current through the HV winding is less compared to LV windings, hence there is less “wear” on the tap changer contacts. Due this low current, in on load tap changer the change over spark will be less.

Terminals

In all transformers, the H terminals are always the high voltage terminals and the X terminals are always the low voltage terminals. Either can be designated primary or secondary depending on which is the source and which is the load.

Spade Terminal

Spade terminals are designed to mate, connect, or terminate a single wire to a screw or stud-type electrical connection. The shape of the spade connector resembles a fork, making it easy to connect or disconnect the spade terminal to the electrical connection.

Spade terminals are used to connect or terminate a single wire while it is connected to a stud or screw type used for an electrical connection. Since the shape of the spade is similar to a fork or spade, it's shape allows you to quickly set screws in place.

Nameplate

The nameplate always indicates the size of the transformer in terms of how much apparent power (rated kVA) it is designed to deliver to the load on a continuous basis.

Transformer kVA Rating

The nameplate always indicates the size of the transformer in terms of how much apparent power (rated kVA) it is designed to deliver to the load on a continuous basis. By its very nature, the transformer will have more than one rated voltage, depending on which side we are looking at and how many windings there are on that side.

Transformer Voltage Ratings

The following is a list of some conventions for specifying transformer voltage ratings:

Transformer Rated Frequency

The rated frequency will also be indicated on the nameplate (usually 60 Hz for the United States). Operating the transformer at a lower frequency will increase the core flux unless the voltage is reduced, this could cause magnetic saturation of the core and overheating due to increased hysteresis and eddy current losses.

Maximum Temperature Rise

The maximum allowable temperature rise for the transformer is also shown on the nameplate and is based on an assumed ambient temperature of 30oC.

Insulation Class

The insulation class indicates the type of transformer insulation.

Transformer Percentage Impedance

Percent impedance is a representation of the impedance of the windings referred to one side of the transformer. This number is the percentage of rated voltage that must be applied to the high side to cause a rated current on the low side when the low side is shorted.

Other items that may be on the nameplate include the number of phases, a Wiring diagram, and tap-changing information.

Transformer Nameplate Information

Following is the key information which is provided on the transformer nameplate from the manufacturer.

(1) Fuses

Daelim Pad-mounted Transformer has two fuse systems: Bay-O-Net fuses and Current Limit Fuses.

(2) Load break switch

For loop feed Pad mounted transformer, usually use one of 4 position load break switch, also Daelim can design 3 of 2 position load break switch instead of 4 position load break switch. For Radial feed Pad mounted transformer, one of 2 position load break switch will be enough.

(3) Tap Changer

Tap changer is for the high voltage taps, usually is ±2.5% of the rated voltage. If customer need special customized taps, Daelim engineer team can also design based on customer’s needs.

Learn more about Tap Changer.

(4) Gauges and Valves

For gauges, there are oil level gauge, pressure vacuum gauge, thermometer (dial-type oil temperature thermometer).

For valves, there are a drain valve with a sampling device, pressure relief valve, and fill plug.

These gauges and valves are located in the secondary compartment.

4. 2000 KVA Pad Mount Transformer Testing

Before shipping our transformers to the customer, Daelim always makes sure that our transformer is perfectly suitable with the customer’s requirements and will 100% work safely. So we have our factory quality inspection and testing before packing and shipping.

We require that each of our transformers must be in strict accordance with the corresponding standards before leaving our factory, undergo appearance quality inspection, and electrical parameter testing, and organize the experimental data into a test report.

After the customer has fully confirmed that it is qualified, it is allowed to leave the factory. Our principle is to resolutely not leave any potential problems to the user site.

l Insulation winding;

l resistance;

l Ratio experiment;

l Excitation current;

l Impedance;

l Winding resistance;

l 48-hour tank leak test;

l empty load loss;

l Withstand voltage test;

l Insulation test, etc...

If any special testing is needed by the customer (such as 24 hours temperature rise test), we can also do it before packing.

After all the tests are completed perfectly, we will offer the test report to the custom

Daelim always supports our customer with the most suitable solution, with the fastest design and production, safest testing, packing, and shipping. If you have any projects need 2000 kva pad mounted transformer, welcome to click here and share your requirements with us!