ANSI/IEEE & CSA Standards with UL Certification Pad-mounted Transformer Production - Daelim Electric Transformer Factory

2022-02-22 | Exhibition Information

As a professional transformer factory, Daelim Pad-mounted Transformer can be standard designed based on ANSI/IEEE standards or CSA standard, or it can be customized designed with accessories by customer’s requirements. You may wonder about the transformer production? Today we are sharing these from Daelim transformer factory:

Pad-mounted Transformer production is similar with power transformer production process, mainly including the following processes: Designing; Winding; Drying; Transformer Assembly; and Testing.

Designing - Daelim Pad-mounted Transformer Production

With a professional engineering department, Daelim can finish the designing work and send the production specification and drawing to the customers in a short time, after we get the confirmation from customer, Daelim production department will start to purchase the materials and start to manufacture.

Daelim’s transformers factory locates in a transformer industrial area, materials suppliers are near with us and it can help Daelim to offer the fastest lead time in the market.

Winding - Daelim Pad-mounted Transformer Production

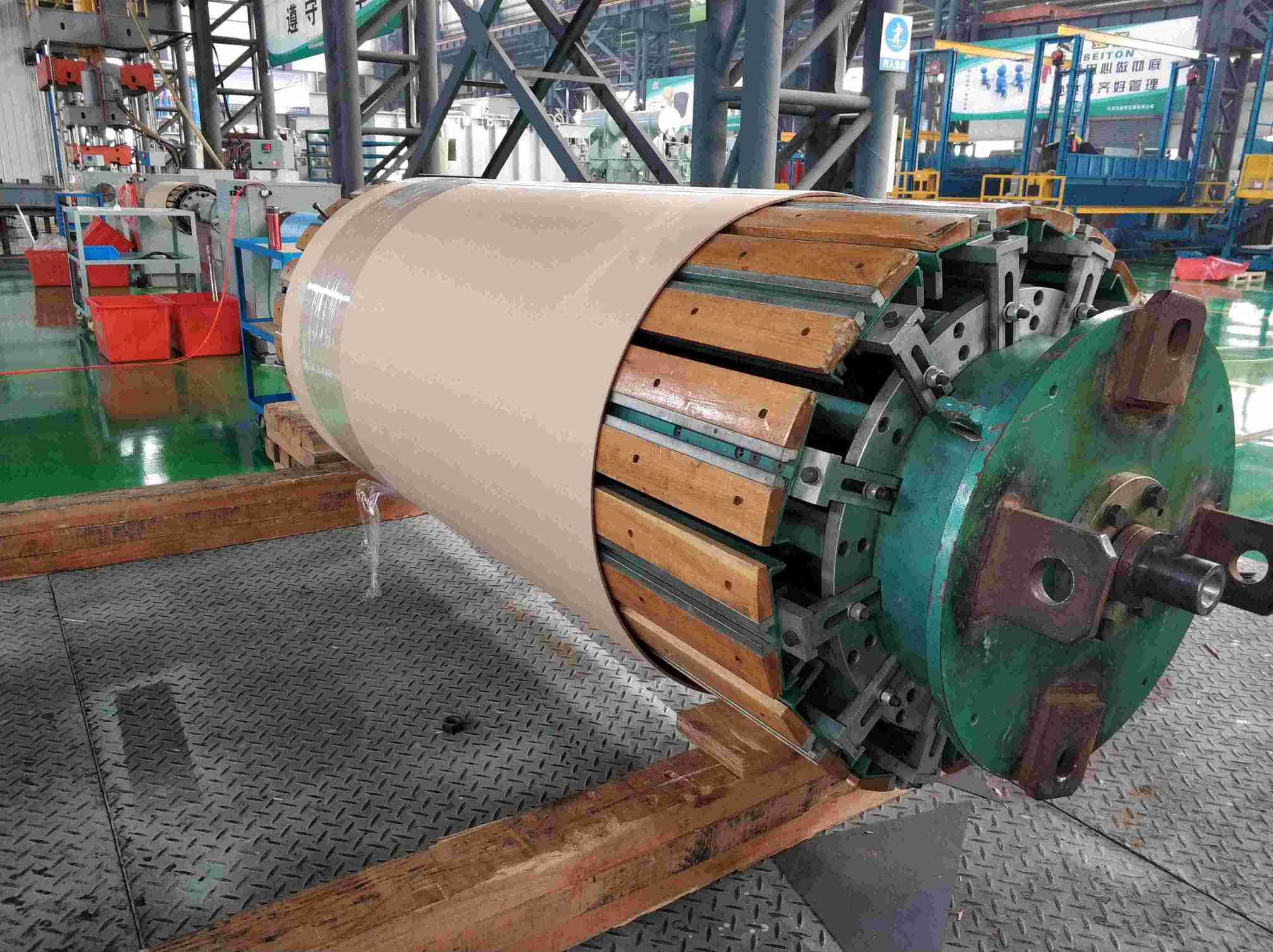

Winding is a very start step of the power transformer production process, it’s to produce the main body of the pad-mounted transformer. Details are as below:

Set the number of turns and the thickness of the copper wire to be wound on the skeleton according to the technical parameters, separate the primary pole and the secondary pole with wires;

Winding requires tight and no gaps;

Strictly ensure the radial and axial geometric dimensions of the winding after press-fitting; Strictly control the cross-sectional size, surface roughness and inter-turn insulation thickness of the wire.

Daelim transformers factory has automatic winding machine for the transformers winding, it helped a lot to faster our lead time.

Drying - Daelim Pad-mounted Transformer Production

Drying is a very important step of the the power transformer production process, it’s to make sure that there are no moisture in the transformer main body before the transformer assembly.

The removal of water in the body of the device is divided into three stages:

• Warm-up stage: the heater body makes the temperature of all parts of the body reach 105-110 ℃ evenly.

• Low vacuum stage: continuously pumping air to remove water, the temperature of the body continues to rise during this process, and enters the continuous vacuum stage after reaching

the set temperature.

• Continuous vacuum stage: Depending on the capacity, it lasts for 4-10 hours, and the drying can be considered complete.

Daelim transformers factory equipped with transformer drying oven, 24 hours working for the fastest production.l

Transformer Assembly - Daelim Pad-mounted Transformer Production

As the last step of power transformer production process, transformer assembly is very important to make sure that all the parts are conform to customer’s requirements. All the transformers must be assembled within 12 hours, and the body of the transformer must be installed in the transformer tank.

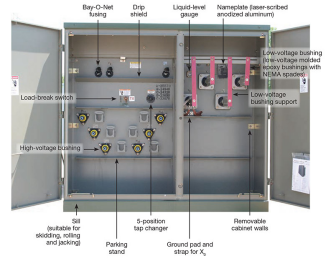

Additional accessories for Pad-mounted Transformers:

High and low voltage bushings, current limit fuses, bay-o-net fuses, oil level gauges, oil temperature gauges, winding thermometers, load break switches, pressure relief valves, etc...

If customer has any special requirements on the transformer accessories, Daelim team can design and produce with no problem, please inform us in the quota stage.

Factory Quality Inspection and Testing - Daelim Pad-mounted Transformer Production

Before ship our transformers to the customer, Daelim always make sure that our transformer is perfeculy suitable with customer’s requirements and will 100% working safely. So we have our factory quality inspection and testing before packing and shipping.

We require that each of our transformer must be in strictly accordance with the corresponding standards before leaving our factory, undergo appearance quality inspection, and electrical parameter testing, and organize the experimental data into a test report.

After the customer has fully confirmed that it is qualified, it is allowed to leave the factory. Our principle is to resolutely not leave any potential problems to the user site.

l Factory testing:

l Insulation winding;

l resistance;

l Ratio experiment;

l Excitation current;

l Impedance;

l Winding resistance;

l 48-hour tank leak test;

l empty load loss;

l Withstand voltage test;

l Insulation test, etc...

If any special testing are needed by the customer (such as 24 hours temperature rise test), we can also do it before packing. More information: click here

After all the tests are completed perfectly, we will offer the test report to the customer.

Packing - Daelim Pad-mounted Transformer Production

After customer confirm our testing report, the Pad-mounted Transformer is ready to ship to the customer! Before send transformer to the port, there is one more import step to do, which is packing. Our transformer will take around 30 days on the sea to our customers in North America or Latin America, the packing must be done in a very safe way.

After four years of updates and constant adjustments to our packaging plan, finally through communication with industry experts and international market customers, we finally decided to

use at least two layers of wooden pallets for transformer packaging under 3 tons and transformer packaging over 3 tons. Use at least three layers of wooden supports to confirm the center of gravity of the transformer and fix it with rivets. In addition, it also provides customers with two packaging solutions, one is a wooden pallet, and the other is a fully enclosed wooden box.

All exported transformer woods are solid wood fumigation logs, and have an English fumigation certificate issued by a professional organization.

To know more details: click here

Shipping - Daelim Pad-mounted Transformer Production

After packing the transformer with our safest solution, the final step is shipping.

Daelim’s transformers factory locted in Taizhou City, Jiangsu Province, which very near to Shanghai port. And we usually offer two solutions for the customer:

1. FOB Shanghai:

If the customer has a good shipping agent who can support with oil-immersed transformer’s shipping, we can make the business by FOB Shanghai.

2. CIF:

If the customer’s shipping agent has no experience with oil-immersed transformer, or they wants Daelim to handle the shipping part, we will quote the customer with CIF price to the most convenient port for the customer.

For all the different ports around the world, our company has professional transformer transportation and freight forwarding, which can provide customers with diversified and customized long-distance shipping solutions.

Examples of our successful projects:

The best Transformers for Bitcoin and Cryptocurrency mining

This year China's ban forces some bitcoin miners to flee overseas, others sell out. This was a big opportunity for some countries special in North America that receive all this new income mining industry. Our company had support this industry developing the best solution for their needs and quality requirements. Last month DAELIM BELEFIC produced and exported 100 units of Pad Mounted Transformers with a capacity of 2500kVA, 13.8kV Delta, 415Y/239.6V in a lead time of 15 weeks to USA. One of our biggest advantages for this industry is that our production process can make us reach faster lead times in order to complete our orders. We also count with special engineers specialized in the cryptocurrency mining transformers.

Australian Transformers based on AS/NZS Standards

One of our main markets is Australia, and the following their AS/NZS Standards is something that our factory has adapt perfectly in the last past 8 years. Our company develop last week a project of 26 units of substations transformers with a capacity of 1500-3000kVA, 33/22/11kV with KNAN refrigeration based on vegetable oil. The price of our transformers in Australia normally are around 20% more competitive. DAELIM BELEFIC has develop a logistic network that allow us give the best delivery times in this country.

The fastest solution for Transformers in Canada

Our company knows that the production time is one of the most important issues in the transformers industry. One of our biggest clients in Canada requested the fastest delivery time for 28 units of 3000&3750kVA capacity and 24.94kV/600V. We make it 7 weeks production time after the drawing was approved. We are more than happy to accept any kind of challenges to support our clients. Finally last week we delivered all the transformers in time and waiting for our next challenge.

DAELIM BELEFIC Experts in Canadian CSA Standards

Our company develop a CSA Standards approval for 3 units of substations, 5000/6667 kVA capacity XFO. One of the most satisfactory feeling to our company is know that we have the ability to manage almost any standard in order of our clients and projects. Last week we got certified CSA for this project making our factory one of the few in China to achieve this standard certification.

UL certification for 4000 kVA & lower TR

USA market is one of the most competitive in the continent and probably the whole world. For that reason and in order to reach all our clients requirements, our factory is listed UL in order to support more projects. In our experience this is one of our higher achievements that help us be more reliable in USA

OEM Pad Mounted Transformer Agreement

We want to celebrate our one year OEM Agreement for 500 units in one year with one of the most experienced companies more than 50 years manufacturing and supplying transformers all around North America.