What to know about a 1000KVA Pad Mounted Transformer|Daelim Belefic

2022-03-16 | Exhibition Information

As a power distribution transformer of the whole power system, a 1000 kva pad mounted transformer is very common in the electric industry. Most of them are used in public utility projects, solar farms, data centers, bitcoin mining farms, etc...

For public utility projects, solar farm projects, the bidder usually has very strict technical requirements based on their local standard; and for data centers and bitcoin mining projects, the users always need a very fast lead time to make sure their project can be done without any delay.

Here at Daelim Belefic, you will have a suitable technical solution plus the fastest lead time in the market, all these advantages together made us successfully support our customers to won contracts, and to finish their projects on time.

Today we are going to check out the 1000 kva pad mounted transformer’s technical information, common questions from customers, and new pictures sharing.

1. 1000 KVA Pad-mounted Transformer Specification

(1) . Standards

When we talk about 1000 kva transformer specification, first should focus on the transformer standard, which is the basic of a transformer’s technical specification.

In the Canadian market, 1000 kva pad mounted transformer should be designed based on CSA C227.4-06 standard, which is for the three phase pad mounted distribution transformer with separable insulated high-voltage connectors. Rated at 3000KVA or below, with an insulation class of 35KV or less.

In the American market and other Latin American countries ( Panama, Chile, Mexico, Honduras, Venezuela, etc...), 1000 kva pad mounted transformer should follow the ANSI/IEEE C57.12.34 standard, which is for Pad-mounted, Compartmental-type, Self-cooled, Three-phase Distribution Transformers, with rated capacity as 10MVA and smaller; High-voltage as 34.5kV nominal system voltage and below; Low-voltage as 15kV nominal system Voltage and below.

And for the USA market, the electrical efficiency should be based on the DOE-2016 standard. For the 1000 kva pad mounted transformer, the efficiency should be 99.43%.

(2) . Accessories

Daelim designed the 1000kva Pad-mounted Transformer based on the customer’s local standard, if the customer or the project has special requirements on the accessories, Daelim can also do a customized design based on the customer’s needs.

High Voltage Bushing:

High-voltage bushings shall meet the dimensional and electrical requirements of IEEE 386. The

minimum continuous and short-circuit current-carrying capabilities of components for looped primary cable systems shall be 200A RMS continuous. If the customer needs 600A bushings, we can also supply based on the customer’s requirements.

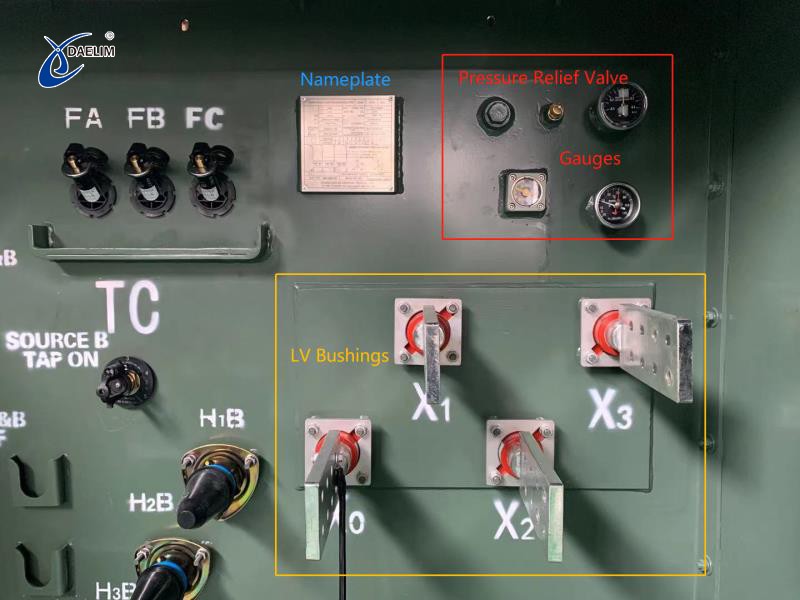

Low Voltage Bushings:

The low-voltage bushings shall be of plated corrosion-resistant metal, suitable for use with copper or aluminum connectors. The low-voltage neutral shall be connected to an insulated terminal, designated X0, with a current-carrying capacity equal to the other low-voltage terminals.

Learn more about transformer bushings, click here

Two Fuse System:

Daelim Belefic 1000 kva pad mounted transformer designed with a two fuse system, which includes an under-oil partial-range backup current-limiting fuse (CLF), a replaceable Bay-O-Net fuse. For dual-voltage transformers, the current limiting backup fuse shall have a fuse voltage rating suitable for the higher voltage and a current rating adequate for the lower voltage. Expulsion fuses for both voltages and corresponding currents shall be provided, and the fuse for the higher voltage shall be installed unless otherwise specified by the customer.

Learn more about fuses, click here

Load-break Switch:

Three phase, oil immersed load break switches for 1000 kva pad mounted transformer, can be 3 units of two position load break switches or 1 unit of four position load break switch. Depends on the customer’s requirements. Shall be hot stick operable, rated 38KV phase to phase, 150KV BIL. Shall be 300 A continuous, operable between -40℃ and +120℃.

Tap Changer:

Off circuit tap changers and dual-voltage selector switches, shall be externally operable lever handle types, made of corrosion resistant material. High voltage taps shall be ±2.5% and ±5% of the rated voltage. If the customer needs a J tap tap changer, Daelim can also support with.

Gauges:

Oil level gauge, Thermometer, Pressure relief valve, Fill plug, Drain valve.

(3) . Routine Tests

The ratio on each connection test;

Angular displacement test;

No-load losses at 105% rated voltage test;

Exciting current at 105% rated voltage test;

Load losses and impedance at rated current, on the rated voltage connection, corrected to 85℃. This test shall be performed on the high voltage connection that has the highest measured loss value;

Applied voltage test;

Induced voltage test;

Transformer tank leads detection test. Shall be performed on each tank to verify the integrity of the welds and on the final assembled unit without the pressure relief device.

(4) . Standard Type Tests

Resistance test;

Temperature rise test;

Impulse strength test;

Radio-influence voltage test;

Short-circuit test;

Transformer integrity test;

Audible sound test.

2. 1000 KVA Pad-mounted Transformer Nameplate

The 1000 kva transformer nameplate should include basic information of this transformer, such as rated capacity, rated high voltage, low voltage, oil weight, and total weight, efficiency, taps, connection group, design & production standard, manufacturer information, etc...

3. 1000 KVA Pad-mounted Transformer Size & Weight

The reference size of 1000kVA Pad-mounted Transformer is:

1730mm*1800mm*1500mm (W*H*D)

The reference weight of 1000kVA Pad-mounted Transformer is 4100kg, with 1500L transformer oil.

4. 1000 KVA Pad-mounted Transformer Packing & Shipping

Packing and shipping is the last step of international business, but for Daelim, it is very important to finish the project by making a perfect packing and fastest shipping to the customer.

The mission of Daelim Belefic is to deliver safe, reliable, and secure transformers to our customers in anywhere on this planet. After years of international business, Daelim has always tried to improve our packing and shipping solution to finish our job in a perfect way and make our customer's satisfied.

For 1000kva pad mounted transformer. Daelim uses wooden case or wooden pallets depending on the project situation. For LCL shipment, we will use wooden case packing to make sure that the transformer is well protected in the container. For full container shipping, we use wooden pallets to save the space in the container so that we put more transformers in one container at the same time.

Check out this article for more detailed information about Daelim's packing of pad mounted transformer: Pad-mounted Transformer Packing Process.

Shipping of the oil immersed transformer is different from other goods you purchased from China. Due to there being transformer oil inside of the transformer, and the transformer is very heavy, it needs an experienced shipping agent to handle the shipping. Daelim has worked with several shipping agents for oil immersed transformer shipping for years, we can do CIF or DDP directly to your address if needed. Our shipping agents will support the customer with the fastest shipping solution.

As a pad-mounted transformer manufacturer with rich experience, Daelim Belefic has a professional system from sales to production.

A sales team with rich experience in the American market, and good communication skills with our international clients. They are responsible for the customer requirements checking, sharing with Daelim engineer team, and getting the feedback to the customers. They are the bridge between the customer and the engineer team. With high working efficiency, they will support the customer with the fastest response.

A professional engineer team is the core of Daelim Belefic. Daelim engineer team is professional with ANSI/IEEE, CSA, IEC, AS/NS, DOE standards, with rich experience in the international electric industry, they will make the most suitable and cost friendly transformer solution for the customer, support our customer to win the order, and if there are any after sales problems, our engineer team will also give their solution to help our customer and make sure the transformer is working perfectly.

The hard working production team is also the ACE of our transformer manufacturer. Daelim production team is not only working hard but also working smart, even Daelim has many orders at the same time, our production team can make the most suitable production schedule to make sure that our transformers will be shipped to the customer on time. With rich experience in the international standards transformer production and testing, our transformers will be well produced and tested before shipping to the customer. We will also send the transformer factory test report to the customer before shipping to confirm.

Last but not least is our packing & shipping team. As mentioned, packing and shipping are very important as the last step of the international transformer business, our packing & shipping team is responsible to do the safe packing and book the ship for the customer. Make the shipping solution based on the project situation, a most cost friendly and fast shipping will make our customer satisfaction from the beginning to the end.

If you have any projects, no matter is public tender, or directly purchase, welcome to share with us anytime. Daelim Belefic is here to support you with the best solution.

Contact us for a free 1000 kva pad mounted transformer solution.